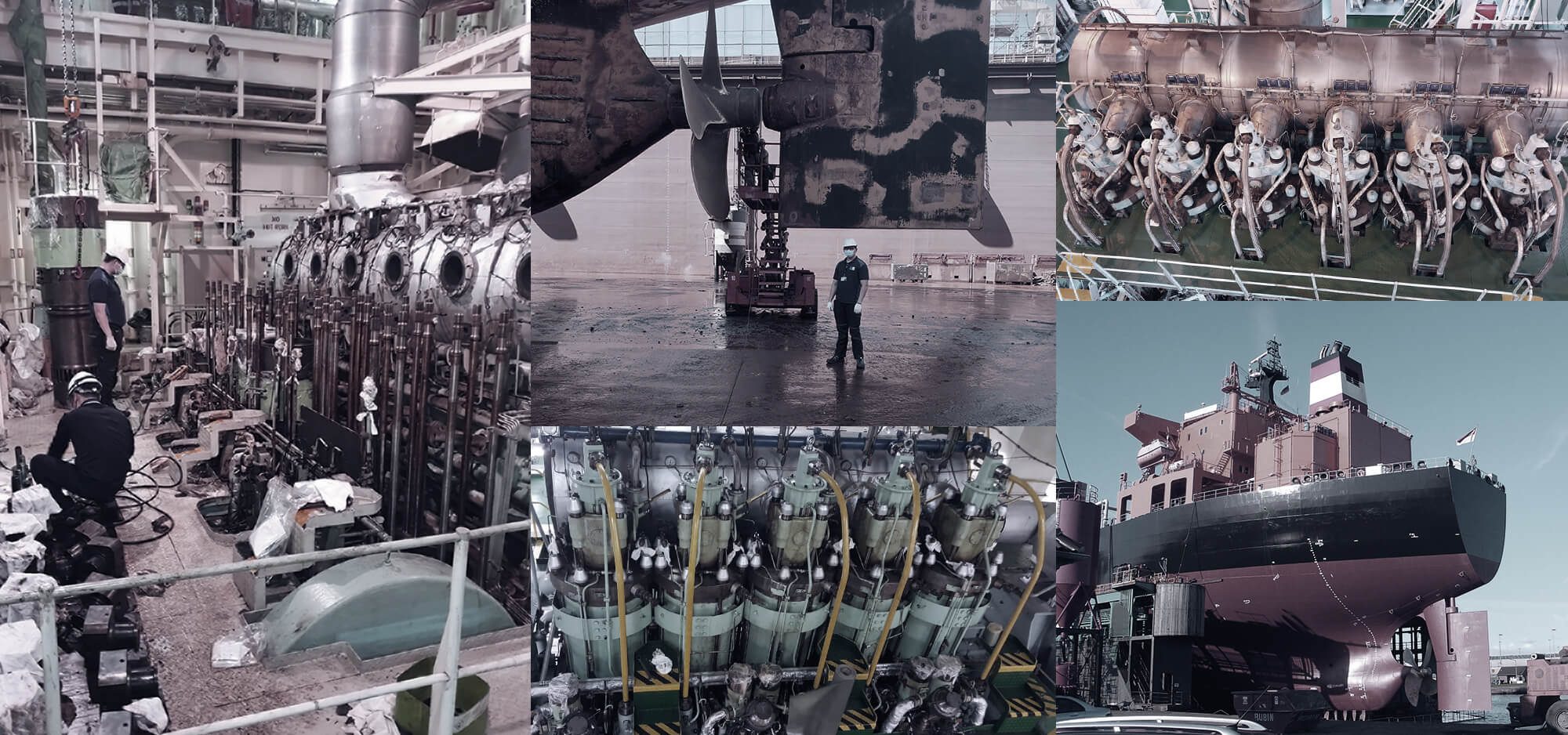

We focus on key repairs that increase the performance and reliability of your vessel’s main engine, while keeping your operating and maintenance costs at a minimum.

Our services

Mardexs Denmark offers a wide variety of services aimed at increasing the performance and reliability of main engines

Services range from pre-dock maintenance, to troubleshooting, and complete dry dock engine overhauls.

Modification of Alpha/ME lubricators

Modification of Alpha/ME lubricators considerably improves main engine cylinder condition and reliability. Following the modification, cylinder oil is injected with higher frequency, resulting in fewer dry revolutions, and extending the time between engine overhauls.

Maintenance of Engine Control System (ECS)

A properly functioning Engine Control System is crucial. Mardexs performs a Health Check of the ECS on all ME-type engines - a pragmatic maintenance solution, which is near-impossible for the crew, and considerably reduces repair costs.

Maintenance of pneumatic systems

The pneumatic system on MC-type engines is crucial for the overall engine reliability, not to mention start-up and maneuvering procedures. With Mardexs dry dock maintenance, engine start-up difficulties are eliminated.

5-year Main Engine Overhauls

Mardexs supervises 5-year dry-dock engine overhauls based on the findings from the pre-dock survey. The overhaul is carried out with a key focus on engine reliability, optimizing operating and maintenance costs.This covers areas not mentioned in the manuals, and often not known by the crew.

Pre-dock main engine survey

Based on a preliminary 17-question engine survey, conducted in close cooperation with the vessel's chief engineer (and superintendent), Mardexs will prepare the engine overhaul pre-dock - including recommended scope, recommended spare parts, and time estimates.

Troubleshooting

Mardexs provides instant troubleshooting and support in case of engine malfunctions. Whatever the problem, Mardexs will assist to have the engine running within hours.

Troubleshooting tasks can include:

Cylinder condition (repeated failure of piston rings, high wear rates, corrosion) | Performance evaluations (underperforming vessels, low pool points, engine tuning, hull/propeller performance, etc.) I ECS on ME engines (operating issues, auto tuning, abnormal alarms, discrepancy of cylinder pressure or fatal stops) | Pneumatic system on MC engines (i.e. issues starting, reversing or increasing loads) | Repeated bearing problems | And more.

Case Stories

With over 30 years in the industry, the Mardexs crew has seen and solved almost every vessel engine problem imaginable

2024

Reconditioning of HPS pumps from MAN ME type engines.

Mardexs reconditioned the Hydraulic supply pumps for a German owner with container vessels in our workshop in Shanghai.

2023

Maintenance of engine control systems.

Mardexs attended German container vessels with MAN 11K98ME-C engines, carrying out total maintenance of the engine control systems including reconditioning of the hydraulic supply pumps.

2022

Upgrade of cylinder lubricators on a series of Danish Gas tankers with MAN ME-C and ME-B engines.

Mardexs attended the vessels in various ports to carry out the upgrade which has reduced volume of injected cylinder oil at a higher frequency. The result is an improved cylinder condition leading to longer time between overhauls.

2021

Following a cylinder unit overhaul on a 181043 DWT bulk carrier, the cylinder liner and piston appeared to be damaged.

Mardexs Denmark was urgently called to attend the vessel for investigation. We conducted a repair of the damage with the vessel’s crew, and during the process we concluded that the cylinder cover was out of balance by design, and therefore wrongly assembled. The vessel crew was instructed how to compensate for the unbalance.

2019

The MR tanker with G50ME-B main engine suffered from poor performance. The cylinder pressure was out of range.

Communication with the vessel revealed that the compression pressure could not be controlled. It was recommended to replace the exhaust valve timing piston. Later the piston was replaced and the performance was normal.

2018

During handover of a sold MR tanker, it turned out that the main engine was in very poor condition. All pistons had to be changed.

Mardexs Denmark was called to attend the vessel. All six pistons were replaced by the vessel crew in 5 days, and the vessel became fit for duty.

2017

A handy-sized chemical tanker earned less pool points than expected.

After being contacted by the vessel superintendent, Mardexs requested a full set of performance observations. The thorough evaluation of the data revealed that the hull was fouled and therefore the speed reduced.

2024

Five year maintenance to engine control systems.

Mardexs attended a series of Danish tanker vessels for a total of five years, carrying out maintenance of the engine control systems, upgrade of the cylinder lubricators, and supervision of the main engine work carried out by the ship yard.

2023

Second special survey dry dock.

Mardexs attended a series of Danish tankers with MAN 6S50MC-C engines for maintenance of the pneumatic control systems, maintenance and upgrade of the cylinder lubricators, and supervision of the main engine work carried out by the ship yard.

2022

Five year maintenance of engine control systems.

Mardexs attended a series of Danish container vessels for a total of five years, carrying out maintenance of the vessels’ engine control systems.

2020/21 and 2015/16

In 2020/21 a series of 8 Oil/Chemical MR tankers were dry docked.

Mardexs was engaged for supervision of the main engine overhauls, and an overhaul of the pneumatic control system. These services were repeat-jobs from the same vessels in 2015. It was quite clear to the customer that the careful review of the main engine, the careful supervision, and the quality of our service in 2015, had resulted in 5 years of reliable, continuous service. Prior to the dry dock, a 17-question pre-dock engine survey completed by the vessel’s chief engineers revealed the engine condition to us. The extent of the overhaul was determined and recommended to vessels superintendent, along with a list of recommended spare parts. Careful supervision and maintenance of the pneumatic control system has set-up the engines for another 5 years of reliable operation.

2018

A Panamax tanker was about to shift from anchorage to port. The pilot was on the way. The start test failed.

Mardexs was urgently contacted. Short communication with the vessel revealed that a specific pneumatic valve had failed. The vessel was guided to replace the stop valve, and the engine started successfully.

2017

A 82800 cubic PLG tanker was not able to reach the ordered speed. The engine torque protection prevented the engine from picking up RPMs.

An investigation of the engine performance revealed that the fuel index was higher than expected. It was concluded that the fuel injection pumps were worn out. Temporarily, the protection curves were raised to accommodate the higher index. The vessel could proceed at ordered speed.

2011

A container vessel loaded with 8000 containers was stuck in Tanjung Pelepas, Malaysia. The engine was a 12K98MC. The vessel had recently been in dry dock.

Making the trip to Europe from the far east, the crew discovered loud noises from the crank case. It turned out that one crank pin bearing had been left untightened from the yard. The problem was temporary solved by removing the connecting rod, and running on 11 cylinders. When arriving in Tanjung Pelepas, the vessels chief engineer heard more noise from the engine. From Malaysia the vessel was bound for Suez, passing the piracy area at Somalia. Engine failure in the piracy area would be fatal, and the fleet management wanted to be assured that the vessel could proceed. Mardexs was called to Tanjung Pelepas. After examination of the engines internals, and running the engine from Tanjung Pelepas to Port Kelang, we could assure fleet management, the vessels captain and chief engineer, that the engine could bring them safely through the piracy area and onto Europe.

THE MARDEXS WAY

The best and most efficient way to keep you sailing.

About us

Mardexs Denmark offers a wide variety of services aimed at increasing the performance and reliability of MAN B&W 2-stroke marine diesel engines

With more than 30 years of industry experience, our team of highly qualified and trained engineers offers straightforward technical advice and concepts to optimize operating and maintenance costs.

Mardexs Denmark works tirelessly to keep you sailing.

THE MARDEXS WAY

THE USUAL WAY

PRE-DOCK MAIN ENGINE SURVEY

Thorough 17-question survey to analyse main engine condition.

NO PRE-DOCK SURVEY

The need for engine maintenance is determined by the vessel’s chief engineer, based on the engine’s manual and running hours.

PRE-DOCK OVERHAUL RECOMMENDATIONS

Detailed proposals for main engine overhaul based on pre-dock survey.

NO OVERHAUL RECOMMENDATIONS

Overhaul is planned based on the chief engineer’s evaluation.

PRE-DOCK SPARE PARTS RECOMMENDATIONS

List of necessary spare parts in accordance with engine manual.

NO SPARE PARTS RECOMMENDATIONS

Spare part sets ordered.

COMPLETE ENGINE OVERHAUL

Overhaul conducted by Yard based on pre-dock recommendations. Engine Control System maintenance by Mardexs.

OVERHAUL BY YARD STANDARDS

Conducted with little to no focus on the Engine Control System.

READY FOR YARD DEPARTURE

Fast and secure, eliminating future offhire.

READY FOR YARD DEPARTURE

Often time consuming and incomplete, risk of offhire repairs.

DETAILED SERVICE REPORT

With summary, conclusions, and prioritized recommendations on the first pages.

STANDARD YARD REPORT

Simple summary of dry dock inspection.

About us

Mardexs Denmark offers a wide variety of services aimed at increasing the performance and reliability of 2-stroke marine diesel engines and MAN D&T engines

With more than 30 years of industry experience, our team of highly qualified and trained engineers offers straightforward technical advice and concepts to optimize operating and maintenance costs.

Mardexs Denmark and our partner companies in Korea and Germany work tirelessly to keep you sailing.

THE MARDEXS WAY

THE USUAL WAY

PRE-DOCK MAIN ENGINE SURVEY

Thorough 17-question survey to analyse main engine condition.

NO PRE-DOCK SURVEY

The need for engine maintenance is determined by the vessel’s chief engineer, based on the engine’s manual and running hours.

PRE-DOCK OVERHAUL RECOMMENDATIONS

Detailed proposals for main engine overhaul based on pre-dock survey.

NO OVERHAUL RECOMMENDATIONS

Overhaul is planned based on the chief engineer’s evaluation.

PRE-DOCK SPARE PARTS RECOMMENDATIONS

List of necessary spare parts in accordance with engine manual.

NO SPARE PARTS RECOMMENDATIONS

Spare part sets ordered.

COMPLETE ENGINE OVERHAUL

Overhaul conducted by Yard based on pre-dock recommendations. Engine Control System maintenance by Mardexs.

OVERHAUL BY YARD STANDARDS

Conducted with little to no focus on the Engine Control System.

READY FOR YARD DEPARTURE

Fast and secure, eliminating future offhire.

READY FOR YARD DEPARTURE

Often time consuming and incomplete, risk of offhire repairs.

DETAILED SERVICE REPORT

With summary, conclusions, and prioritized recommendations on the first pages.

STANDARD YARD REPORT

Simple summary of dry dock inspection.

The Bigger Picture

Reduce

repair costs

Most ME engine overhauls are recommended at 32,000 hours, but an oil/chemical tanker will normally reach 22,000 – 25,000 hours between 5-year special surveys. Mardexs Denmark’s ECS Health Check is a pragmatic maintenance solution that considerably reduces repair costs.

ongoing spare

part checks

Mardexs Denmark provides ongoing spare part checks to ensure operating and maintenance costs are optimized between dry dock service, in full accordance with the accepted criteria in engine manuals.

the necessary adjustments

At Mardexs Denmark, we help our customers save money on mainternance and repairs by focusing on the necessary adjustments that will increase the performance and reliability of their vessel engines.

ONLY THE CORRECT

SPARE PARTS

Mardexs Denmark does not sell spare parts, nor do we add re-seller percentages to supplier prices, but we are more than happy to

help our customers purchase the correct

spare parts for their engines.

5-YEAR DRY DOCK

ENGINE OVERHAULS

Mardexs Denmark supervises 5-year dry dock engine overhauls carried out by shore personnel, in order to ensure reliable results and peace of mind for fleet management, vessels captains, and chief engineers.

service

reporting

At Mardexs Denmark, we consider service reporting to be equally as important as the services carried out. In our service reports, you will find SUMMARY, CONCLUSIONS, and RECOMMENDATIONS on the

first pages, highlighting any maintenance

or repair tasks that require

immediate attention.

The Bigger

Picture

Reduce

repair costs

Most ME engine overhauls are recommended at 32,000 hours, but an oil/chemical tanker will normally reach 22,000 – 25,000 hours between 5-year special surveys. Mardexs Denmark’s ECS Health Check is a pragmatic maintenance solution that considerably reduces repair costs.

ongoing spare

part checks

THE NECESSARY ADJUSTMENTS

ONLY THE CORRECT

SPARE PARTS

5-YEAR DRY DOCK

ENGINE OVERHAULS

THE NECESSARY ADJUSTMENTS

Contact us

Mardexs Denmark ApS

Sandtoften 10, DK-2820 Gentofte, Denmark

CVR nr. 32320759

Phone +45 2114 7194

Email erikbrems.kristensen@mardexs.dk

MARDEXS Denmark keeps you sailing

© Copyright 2021 — Mardexs Denmark ApS | All Rights Reserved